Showroom

Our Tensile Test Equipment utilizes cutting edge drives, controllers, and servo engines to play out an assortment of elastic sturdiness and quality tests. Tests incorporate yet are not restricted to BIFMA Broadly useful Office Seat, Parlor Seating, and Work area/Table Execution testing alongside a few other exclusive capacities.

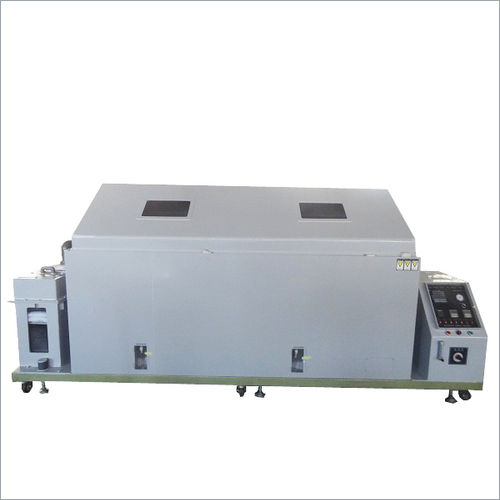

The arrangement of Environment Test Chambers is an awesome decision for cyclic low, high temperature and dampness tests. Worked with the most astounding quality and unwavering quality, this chamber is equipped for meeting the most stringent testing needs of different universal guidelines.

Blasting quality of a material is characterized as the most extreme hydrostatic weight required delivering burst of the material when a controlled and always expanding weight is connected through an elastic stomach to a round territory. This can be estimated through our Luggage Test Equipment.

The zone of the material under test with our Textile Test Equipment is at first level and held unbendingly at the outline yet is allowed to swell amid the test. The test example, held between annular cinches, is subjected to an expanding weight by an elastic stomach.

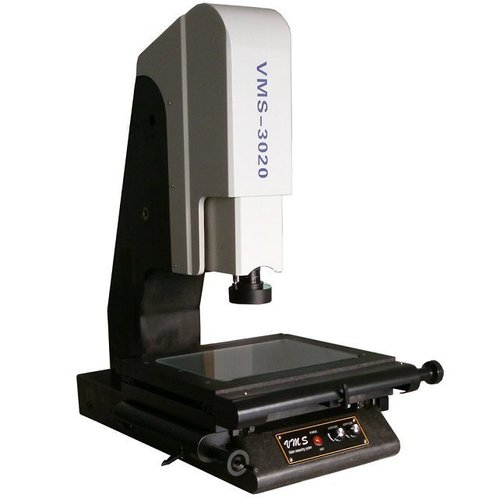

Optical Test Equipment is the transcendent media compose for mission-basic datacenter joins, spine inside structures, and longer separations for grounds systems. As system velocities and data transmission requests increment, separation and misfortune confinements have diminished, making fiber optic cabling accreditation testing more essential than any time in recent memory.

Shoes Test Equipment is intended for estimating the protection of shoes of different types to flex. It decides the exhaustion strength and administration life of shoes by recreating the strolling condition of a man. This shoe flexing analyzer highlights basic operation, sensible plan, inflexibility and sturdiness, low clamor and simple upkeep.

Cookware Testing Equipment is utilized for testing quality of cook wear against heat that is used to the example and the subsequent twisting watched. The security of the item is tried. Temperature dependant avoidance meter is incorporated for successful execution.

Metal Test Machine is for the general test connected to numerous polymers to check the mechanical properties and it is the most vital property as larger part of mechanical stacking and properties like Rigidity and modulus , stretching , compressive quality And so forth are ascertain by utilizing our machine.

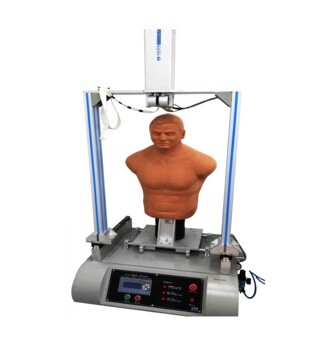

Provided Furniture Test Equipment uses a roller screw direct actuator to apply loads and position with an abnormal state of precision. The actuator is mounted to an extraordinary arrangement of direct heading which permit vertical, even, and corner to corner movement. This is our most flexible machine and will rapidly turn into an irreplaceable piece of your research facility.

Leather Testing Equipment utilized for getting the exact Estimation of material with standing power limit by pull it separated and to figure out what degree the materials can be extended before achieving the limit.

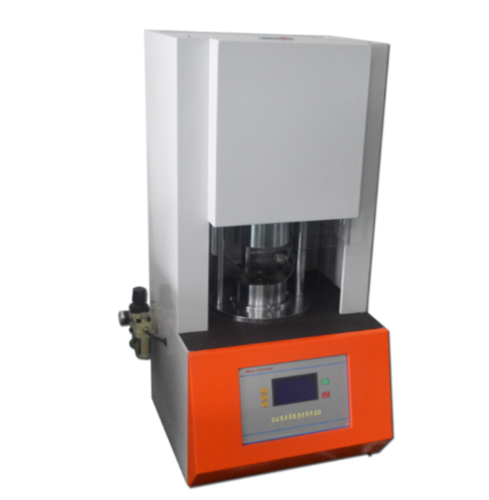

We present the best in grade Rubber and Plastic Test Equipment that accompanies the choice highlights and long administration life. We invest enough energy in understanding the present request in the market that causes us to give the finest caliber machines to our clients.

Conductive channel of the appropriation of the full line all over the street, rail, the utilization of protected boards, collecting electrical conductivity of different lights can be checked with our LED Aging Test Machine. Online base has an insurance hockey net, to avoid off light fell lousy.

In the case of putting in new link, or investigating existing link, our Wire and Cable Test Equipment assumes an imperative part all the while. Basic system tests for datacom cabling incorporate length, wiremap, lessening, NEXT, DC circle protection, and return misfortune.

Baby Stroller / Bicycle / Toys Testing Machine are planned with an assortment of centered highlights for specific field undertakings. They differ in value, execution, and application. Contingent upon the assignment the field test instrument performs, it can be arranged into one of the three various leveled gatherings.

Test and create with certainty knowing this quality affirmation Adhesive Tape Test Equipment has been expertly field tried. What's more, know when you pick our machines, your glue testing lab meets the test hardware gauges suggested by glues and covering associations

Our Universal Testing Machines otherwise called a materials testing machine and can be utilized to test the malleable and compressive qualities of materials. These can play out every one of the tests like pressure, twisting, strain and so forth to inspect the material in every mechanical property.

Testing Machines are the advanced test equipment which are utilized for checking the walking ability, pressure bearing capacity, vibration and strength of the machines. The machines are accessible with advanced testing process and ensure correct, timely, safe and qualitative operation.

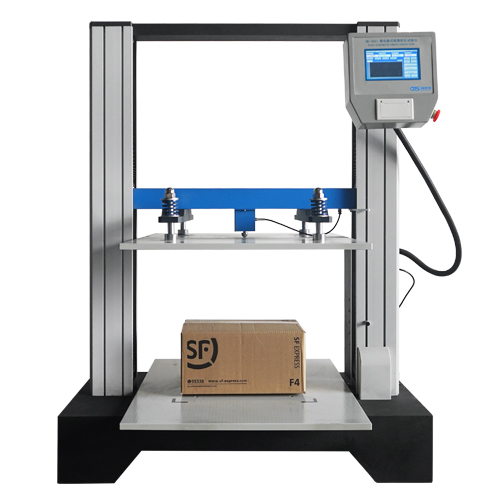

Printing & Packaging Import Test Instruments are profoundly suggested for labs and ventures where it is vital to keep up shading consistency and quality. The hardware gives an institutionalized domain to assessment and visual evaluation of shading. They give speedier, nearer and exact shading coordinating arrangement.

Single administrator can run different production procedures in our Household Electronic Appliances Test Machine. Parallel procedures run at the same time to upgrade time and generation yield. Vertical item maintenance decreases hardware impression. Incorporate quality examinations without affect on time.

|

HAIDA INTERNATIONAL EQUIPMENT CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese