Chair Seat Arm and Back Testing Machine

Product Details:

Chair Seat Arm and Back Testing Machine Price And Quantity

- 2000.00 - 5500.00 USD ($)

- 1 USD ($)

- 1 Set

Chair Seat Arm and Back Testing Machine Trade Information

- shenzhen

- Cash Against Delivery (CAD) Cash on Delivery (COD) Letter of Credit (L/C) Western Union Paypal Letter of Credit at Sight (Sight L/C) Delivery Point (DP) Telegraphic Transfer (T/T) Days after Acceptance (DA) Cash in Advance (CID) Cheque Cash Advance (CA)

- 150 Set Per Month

- 15 Days

- Each set protected with resin fiber and PP film, then put into Strong wooden case with operation manual and video inside.

- Australia Eastern Europe Middle East Western Europe Africa Central America South America Asia North America

Product Description

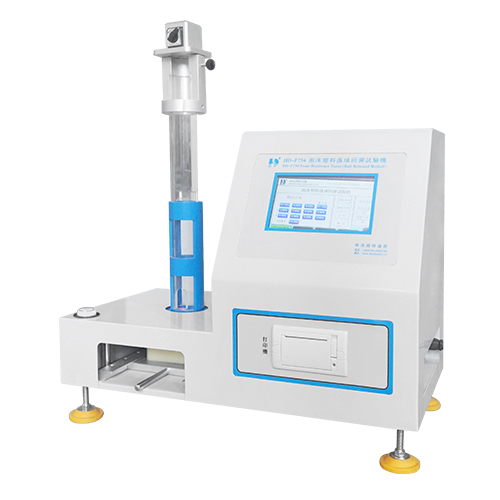

Chair Seat Arm and Back Testing Machine

1 . Introduction :

Sofa Seat Arm and Back Testing Machine is to simulate normal functional use to determine the strength of the sofa structure by applying to various parts with loads or forces . Using certain shape and load modules , with specific form , frequency , respectively , repeating load seat , back and armrest . Each point have force sensor to show the pressure .

2 . Sofa Seat Arm and Back Testing Machine Main technical parameters :

Senor accuracy : 0 . 3%

Control panel : programmable LCD touch screen controller

Maximum specimen size : ( LWH ) 220012001200mm

Seat load : 0~200kg ( adjustable )

Back load : 0~100kg ( adjustable )

Test cyclic : 0~999 , 999 ( adjustable )

Machine weight : 400kg

Power : 1 phase , AC220V , 50Hz

Air pressure : 7kg/cm2

Design criteria : EN4875

3 . Main Parameters :

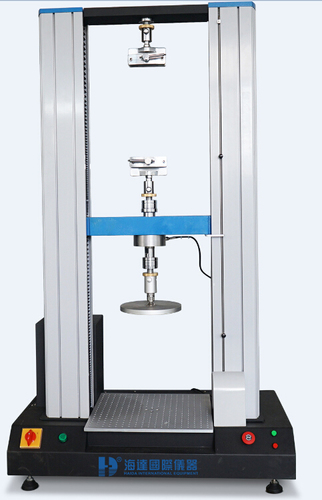

The machine consists form several parts

- Tension mechanism , servo motor and the strap pulley architecture , the intensity of the rotation transformed into tension and supplemented force values turn sensor read correctly tension , the action of the closed-loop control of servo motor to achieve a number of pull . Static and cyclic testing . Rally and speed can be set free . Mainly used for 5 , 6 , 13 , 14 , 15 , and 16 test .

- In addition to this machine is also configured with two groups of electric actuator , respectively , for a group of the vertical apparatus and the horizontal apparatus 1 group , each group independently adjust the speed and thrust . Stroke is 500mm

- The vertical means of the servo motor can be used for the actuator , the vertical position adjustment , mainly used for the first 11 . 4 , 22 , 23 and 24 of the test ; the maximum pressure is 150 kg .

- Level device servo motor caused the brake position adjustment of the pieces up and down and left and right mobile and flexible to meet the demand for different test location , is mainly used for 10 , 12 . 3 and 12 . 4 testing . 50 kg maximum thrust , adjustable up and down the range from 500 mm to 1200 mm.

- the bottom plate of the test machine drilling multiple rows of screw holes for easy installation of different

4 . Attachments and fixed test conditions

- each electric actuator front-end with a quick connector for easy replacement of the load block and fixture

- control mode : PLC with LCD touch screen

- the maximum tension value:150kg

- the maximum thrust value(horizontal):50kg

- the maximum pressure value(Vertical)150kg

- Can be equipped with computers , recording force and displacement changes .

Procedures

If a chair has a pneumatic back tilt or pneumatic seat inclination adjustment mechanism, each is tested. The test uses a four-part cycle as follows: A. A 50-pound load is applied to the seat (seat inclination test) or back (back inclination test) normal to the plane of the seat, or, to the plane of the back. The load is applied to the seat or back at that location that will most easily cause the seat or back to tilt when the tilt activator is operated. B. The load is removed. C. The load is reapplied and the adjustment mechanism is activated while the chair is under load. D. The load is removedwhile the adjustment mechanism remains activateduntil the seat or back mechanism returns to its normal position. Once the normal position is reached, the adjustment mechanism is deactivated. The complete cycle is repeated at a rate of 5 cycles per minute. The test is continued until some part of the adjustment system malfunctions or the chair meets the required acceptance level.

Other Products in 'Furniture Test Equipment' category

|

HAIDA INTERNATIONAL EQUIPMENT CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese