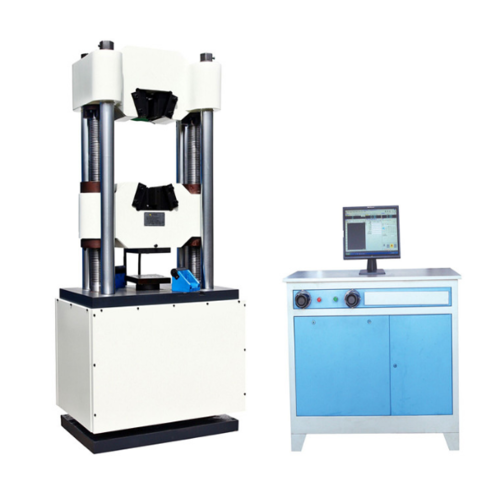

Package Clamp Test Machine

Product Details:

Package Clamp Test Machine Price And Quantity

- 1 Set

Package Clamp Test Machine Trade Information

- Shenzhen China

- Cash Against Delivery (CAD) Cash on Delivery (COD) Delivery Point (DP) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Western Union Paypal Days after Acceptance (DA) Cash in Advance (CID) Cheque Cash Advance (CA)

- 150 Set Per Month

- 15 days after received the order Days

- Each set protected with resin fiber and PP film, then put into Strong wooden case with operation manual and video inside.

- Australia North America Eastern Europe Middle East Western Europe Africa Central America South America Asia

Product Description

Specifications

Package Clamp Test Machine

- Package clamp testing machine

- Up to ASTM D6055

- .PLC control

Safety protection

Overload protection, overvoltage protection & limited position protection device

Clamp Compression Testing Method of Large Products

- Before placing the packaged product between platens, verify that the clamp force using the clamp indicator. The indicator should be placed between the axes of the platen articulation points approximately 1/2 way up the platens.

- .Each time the product is clamped, the force should be applied for a minimum of 15 seconds and not to exceed 1 minute.

- Apply the clamp force on the sample with the platens resting on the floor and the front edge of the platens flush with the front of the package (see flush platen photo 4). If the package is too large for the clamps to be flush to front edge (i.e., large refrigerator, tractor etc.), clamp as close to the edge as possible.

- Clamp the product a total of 10 times in the flush orientation.

| Clamping force | 1T |

| color | optional |

| Resolution | 1/100,000 |

| Test Space(L x W x H) | 100x 100 x 100cm |

| Test Speed | 103mm/min |

| Weight | around 300kg |

| Power | 1#, 220V/50HZ |

Clamp Compression Testing Method of Small Products

Before clamp testing, verify that the clamp for using the clamp force indicator. The indicator should be placed between the axes of the platen articulation points approximately 1/2 way up the platens.

During clamp compression testing of small products, 4 samples will be utilized as outlined below.

1. If, when oriented for clamp testing (based on the handling graphics) the sides perpendicular to the platens of a single sample 24 (61cm), then the 4 sample should be placed in aside by sideoritentation as shown to the fig 1(with 2 samples on the bottom and 2 on the top)

2. If, when oriented for clamp testing the sides perpendicular to the platens of a single sample are >24 (61cm),, then the 4 samples should be placed in a top-bottom orientation as shown fig 2. If, when placed 4-high, any of the samples are completely above the top of the platens, that sample can be removed from clamping in this orientation only(fig 3 shows 3 MHCs ready for clamp testing with the 4th sample removed from testing in this orientation)

3 Each time the samples are clamped, the force should be applied for a minimum of 15 seconds and not to exceed 1 minute.

The Parameters

| Clamping force: | 50-3000kg |

| Size of the clamping board: | 1200 by 1200mm |

| Maximum clamping space: | 1200 by 1200 by 1200mm |

| Minimum clamping space: | 400 by 1200 by 1200mm |

| Clamping speed: | 5-50mm/min |

| Up-down space: | 100-600mm, adjustable, can be customized |

| Dimension: 3 | 810 by 1900 by 2100 |

| Weight: | 800kg |

| Power: | 380v/ 50Hz |

| Control system: | PLC programmed control |

Other Products in 'Universal Testing Machines' category

|

HAIDA INTERNATIONAL EQUIPMENT CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese